Optimization

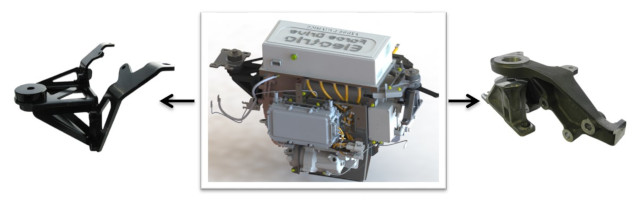

Optimization of an engineering design may occur through analysing the topology, shape and topography, and other parameters such as composite lay-up. Topology optimization starts with the functional constraints such as force vectors and generates the most efficient mathematical shape possible to meet goals such as minimizing mass and material, while shape and topography optimization work to fit a component or system within a certain spacial envelope. Quite often, a component will be developed using topological optimization, and then undergo a topographical optimization at a later stage when manufacturing constraints are applied (such as constraints on wall thickness).

The common goal of applying automation to the optimization process is to reduce or eliminate the design iterations by adding, removing or moving material to optimize on some set of resulting set of measurements such as mass, volume and reliability / durability. In complex designs with many constraints and performance factors, a Design of Experiments (DOE) may be formulated to provide efficient engineering design guidance for a project. Design sensitivity may also be analysed to provide insight on how flexible the design is to modification and accomodation for manufacturing techniques.

TSI uses Altair HyperStudy which is a generic tool for optimization, DOE’s, and stochastic evaluation.