Hydroforming and Bending Simulation

Project Overview

To ensure a reliable and cost-effective solution, we utilized state-of-the-art software — DynaForm and LS-DYNA — to simulate the entire process, from tube bending to hydroforming. This allowed us to conduct virtual trials and explore different parameter sets without the need for expensive physical testing.

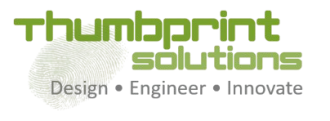

Tube Bending Simulation

We began by simulating the tube bending process. Using CAE software, we carefully analyzed key process parameters such as feed rate, rotation, radius, and bend angle. By adjusting these variables, we were able to see how they affected the final geometry of the rail tube.

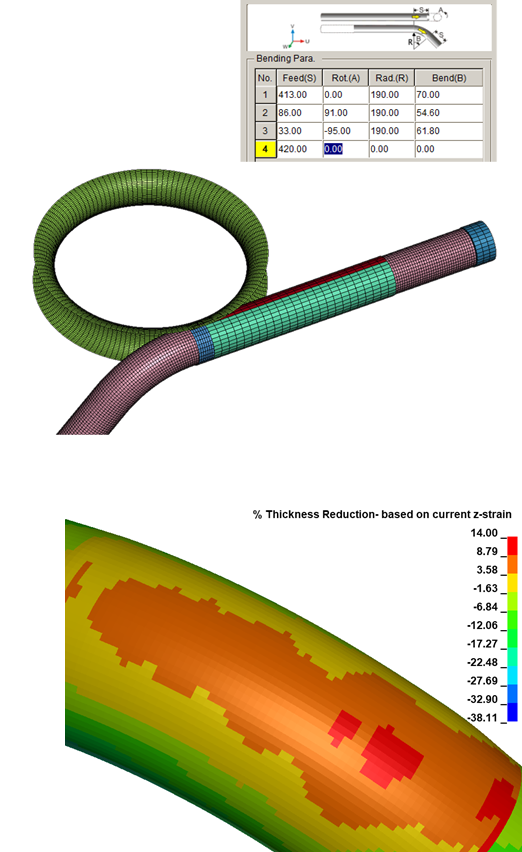

Hydroforming Simulation

After optimizing the bending process, we moved on to the hydroforming stage. Here, we investigated the impact of pressure prefill on the formability of the tube. The simulation allowed us to explore the behavior of the material under hydroforming forces and adjust the process for the best possible outcome.

With both the tube bending and hydroforming processes simulated, we fine-tuned the parameters to achieve the ideal geometry for production. Additionally, we provided guidelines on the maximum allowable tonnage forces for the bending process to avoid any risk of tube buckling—a crucial consideration in maintaining product integrity.

Get in touch with us

Partner with us for innovative engineering and proven solutions that turn challenges into opportunities.