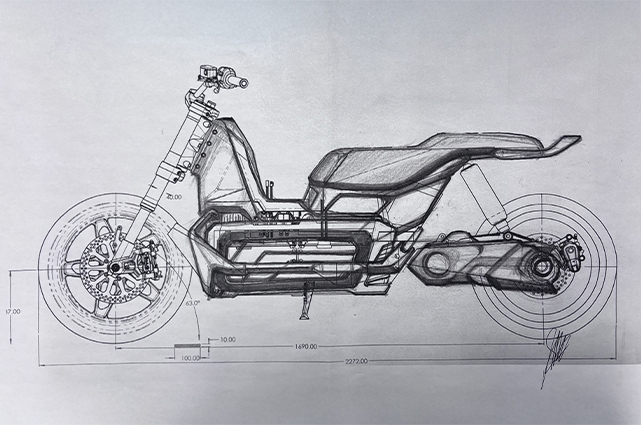

Concept Design

Transforming ideas into practical, manufacturable designs starts with a strong concept. We provide creativity, industrial design and technical expertise to craft compelling concepts to get things going the right way.

System-Level Engineering

System-level engineering provides the backbone for complex machines. We integrate advanced methodologies and tools to model and ensure understanding of our design-space. From concept to implementation, we bring a strategic blend of technical expertise and creativity to drive success across all system levels.

Detailed Design

Our detailed design process is rooted in precision, collaboration, and innovation. Our multi-disciplinary team works closely with clients to transform concepts into fully realized production-ready designs.

Product Launch Enablement

TSI provides end-to-end support for a seamless and successful product launch, ensuring your designs transition smoothly from concept to production. Our expertise spans engineering validation, manufacturing readiness, and supply chain coordination to bring high-quality products to market efficiently.